Your Shopping Cart

Your cart is empty.

Subtotal ( items)

Instant Rebate Applied:

Promo Code Applied: ID.me Discount Applied:

Have a Promo Code?

Size:

Item

Item

Selected for:

/ each

Add-Ons

Wireless air pump capable of pumping up to 150 psi with 2000 MAH power bank.

Fully protect your clothes and vehicle interior during transportation of your tires. For Tires up to 31" tall and wheels up to 22".

Per sensor

Add TPMS Sensors

/per sensor

Please confirm the make, year, model and trim of the vehicle you want to purchase for:

How many sensors do you need?

The vehicle you have selected is not compatible with aftermarket TPMS Sensors.

Enter a different vehicle to add TPMS sensors

Front Tire Size:

Front Tire Size:

Rear Tire Size:

Rear Tire Size:

Your Vehicle:

Your Vehicle:

Pros & Cons of Staggered Fitment

Attractive Design

Improved Handling

Improved Cornering

Bumpier Ride

Poor Traction in Snow

How do I find my tire size?

Need help?

Your Vehicle:

Your Vehicle:

Pros & Cons of Staggered Fitment

Attractive Design

Improved Handling

Improved Cornering

Bumpier Ride

Poor Traction in Snow

How do I find my tire size?

Need help?

Pros & Cons of Staggered Fitment

Attractive Design

Improved Handling

Improved Cornering

Bumpier Ride

Poor Traction in Snow

Need help?

Need help?

How do I know if I have an LT tire?

Your Vehicle:

Your Vehicle:

Sorry, we could not find any available

wheels for your sizing selections.

Need help?

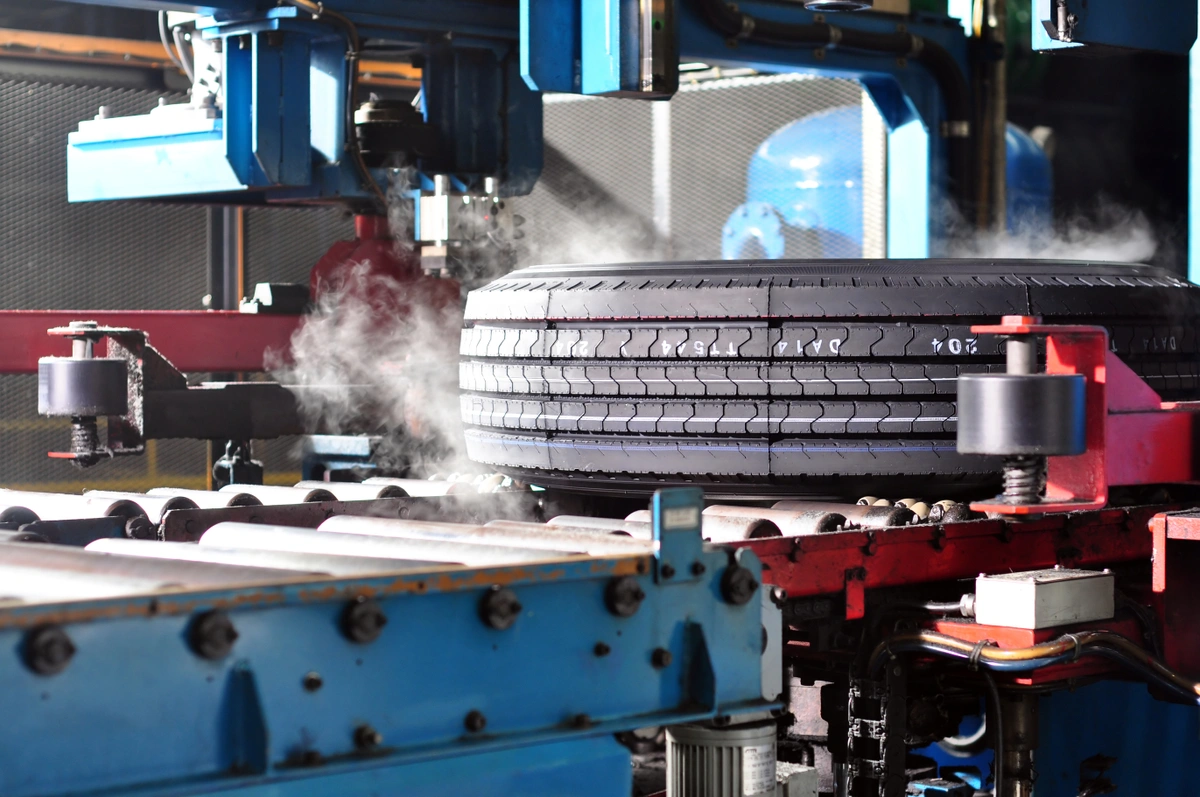

What Is a Tire Made Of? How Are Rubber Tires Made?

By Tire Agent Staff

June 08, 2023

Have you ever stopped to think about what your car's tires are made of?

Tires are made of a complex blend of different rubbers – natural and synthetic, including natural rubber, synthetic rubber, and several types of rubber.

They also contain materials such as natural rubber, synthetic rubber, carbon black, and various chemicals. Additionally, tires incorporate polyester, rayon, or nylon cords within a rubber layer to provide structure and durability.

This combination of synthetic rubber, natural rubber, fabric, and wire ensures tires are strong, flexible, and capable of providing a smooth ride.

So buckle up and join us as we geek out about one of our favorite subjects: tires.

Where Does Tire Rubber Come From?

Tire rubber, as the name suggests, comes from a plant called Hevea brasiliensis (H. brasiliensis). This tree is native to South America but is now grown in other regions including Southeast Asia and Africa. The rubber used for tire production comes from the sap of this tree.

Because of these organic ingredients, tires have about a 6 year shelf life. Before you buy new tires, check their manufacturing date.

The process of obtaining the rubber sap, also known as latex, involves making diagonal cuts into the bark of the tree and collecting it in cups attached to the trunk. The liquid latex is then processed by heating it with acid to coagulate the proteins in it.

Photo: Jumpstory

This video from the Science Channel shows how rubber is processed into sheets.

Once coagulated, the solid mass undergoes various processes such as washing, rolling, pressing or drying before being sent off for further processing into different forms including sheets or pellets that can be used in tire manufacturing.

It's worth noting that while natural rubber remains an essential component of tire-making today, synthetic rubbers such as styrene-butadiene (SBR) have increasingly been developed and are widely used instead due to their superior durability and resistance capabilities.

How Are Rubber Tires Made?

First, raw materials such as natural rubber, synthetic rubber, carbon black, and various chemicals are mixed together in a large machine called a Banbury mixer. This mixture is then heated to a high temperature, which causes it to become a sticky compound that can be molded into different shapes.

Next, the compound is shaped into long strips or sheets and fed through rollers that compress it to remove any air pockets. These sheets are then cut into pieces of the desired size using special machines.

The tire-building process starts with building up layers of rubber around an inner liner to form what's known as a "green tire." The green tire is then placed inside a mold where heat and pressure are applied for vulcanization - the process that binds the components together. After vulcanization, excess material from the edges of the tire is trimmed using specialized equipment. Each tire undergoes rigorous quality control tests before being sent out for use on vehicles.

Making rubber tires requires precision, engineering and attention to detail at every step of production to ensure safety on our roads.

This video from Michelin's YouTube channel shows how more than 200 ingredients are used to make truck tires!

Read more: Anatomy of a tire

What Is the Structure of a Tire?

Understanding the structure of a tire can help you appreciate how it works and lasts for so long. Tires consist of various layers, each playing an important role in ensuring their durability and safety.

The innermost layer is called the carcass, composed of cords running perpendicular to the direction of travel. The sidewall is reinforced with rubber-coated steel wires that give tires their shape while protecting them from damage. The tread layer provides traction and contact with the road.

Between these layers are more components like belts made up of steel or synthetic materials to keep the tire rigid at high speeds. There's a layer called a cap ply which enhances stability while also preventing air pressure loss over time.

Tires are complex structures that require careful manufacturing processes to create compounds durable enough for everyday use on different road surfaces. Knowing what your tires are made up of can help you maintain them better by checking air pressure regularly and rotating them often for even wear distribution.

Main photo 19528764 | Ninthsun9 | Dreamstime.com

How to Qualify for the $50 Offer

- Add items to your cart and begin checkout.

- Select PayPair and apply for financing.

- If you’re approved by a participating lender, you’ll see a $50 promotional rebate applied to your order total.

-

To receive the $50, you must:

- Complete your purchase with a qualifying lender,

- Agree to the payment terms,

- And make the required number of consecutive on-time payments, as specified by the lender.

Note: Offer available only through select lenders. Additional eligibility requirements and conditions apply. Rebate may be issued after verification of qualifying payment activity. Terms subject to change.

How to Purchase Tires and Wheels

With a Payment Plan

Tire Agent's payment plans make it easy to get the best partial or full set of tires and wheels for your vehicle.

It's fast, secure and won't affect your credit score

Match with multiple lenders

Why Choose PayPair?

PayPair’s Partners and Plans

No Money Down

No Money Down

No Credit Needed*

No Money Down

$1 to Start!*

No Money Down

No Credit Needed*

$1 to Start!*

No Money Down

Other Payment Plans

Pay Over Time

Pay with your bank account

Simplified checkout experience

Faster and easier than using cards or cash

Simplified checkout experience

Faster and easier than using cards or cash

*SNAP: The advertised service is a lease-to-own agreement provided by Snap RTO LLC. Lease-to-own financing is not available to residents of Minnesota, New Jersey and Wisconsin. NO CREDIT NEEDED: Not all applicants are approved. While no credit history is required, Snap obtains information from consumer reporting agencies in connection with applications, and your score with those agencies may be affected. PAYMENT PLAN: The standard plan consists of renewable lease terms. To exercise an early ownership, consumers must make regular payments on time and schedule additional payments via the customer portal or by contacting Customer Care at 1-877-557-3769. KATAPULT: The Promotional Initial Payment (plus any applicable taxes and fees) is due at lease signing. Your lease-purchase payment amount will be determined after you select your product(s). You will not acquire ownership of the product(s) if the total amount necessary to acquire ownership is not paid. The Promotional Initial Payment does not reduce the cost of the lease-purchase agreement. The Promotional Initial Payment is only available when shopping at Tire Agent through the Katapult mobile app and at Tire Agent's’s website. Product pricing subject to change and availability. Disclosure: 90-day early purchase option (EPO) terms and conditions apply: 90-Day (3 months in CA) You can buy out your lease-to-own agreement within the first 90-days. This amount includes the cash price, plus the lease-to-own cost for the first 90-days. Taking advantage of the 90-day purchase option will save you the most money! PROGRESSIVE: Ownership by rental/lease agreement with Progressive Leasing costs more than the retailer’s cash price. Select items only. Cancel or purchase early at any time. Not available in MN, NJ, VT, WI, WY. Progressive Leasing obtains information from credit bureaus. Not all applicants are approved. Standard agreement offers 12 months to ownership. 90-day purchase options cost more than the retailer’s cash price (except 3-month option in CA). To purchase early or to cancel lease, you must call 877-898-1970. Retailer cannot activate early purchase options.